Geared Up For Success

Photo by Quinn Martin

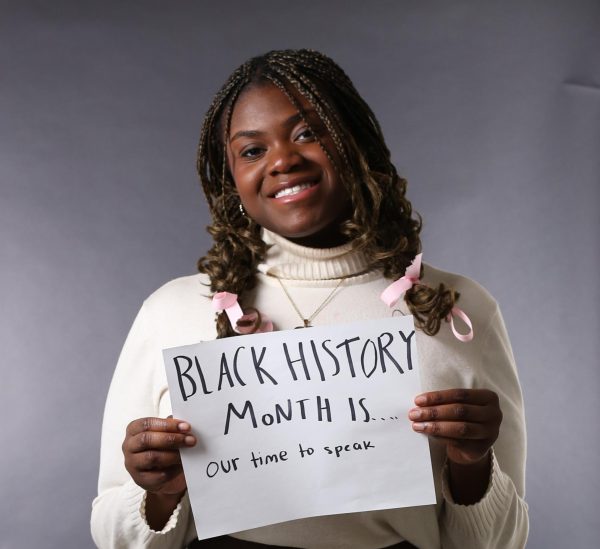

Michael Barger (11, center) works alongside Isabella Ieremias (10) on the teams’ redesigned robot.

Two months ago, the Robotics team was searching for an insert to use in one of their robots for the 2022-23 competition season. They frequently enter competitions held by VEX, an educational tech company. The company is a non-profit, but to participate, robotics teams have to build their robots using parts bought from the company.

The team was making headway with their robot two months before their tournament. They had bought most of the materials, including special wheels from VEX that were sure to give them an edge.

There was only one problem.

An essential piece of equipment, a small insert that would allow them to use specialized wheels, was sold out on the VEX website. Without that insert, those wheels were useless.

As Elena Bowles (10) faced the issue, she could feel the panic racing through the room.

“We needed that part, like a lot,” Bowles said. “It was a big part of our design, and it was very stressful.”

Any modifications they could have made would’ve been too expensive and time-consuming. As the clock ticked closer to the day of the competition, the robotics team was running out of options. That was, until Orion Smith, the team advisor, found a solution. VEX had exact schematics of the insert on their website that would be nearly identical. So, he decided to 3D print them.

The part worked perfectly. The team was elated, hopeful for many wins at the upcoming tournament. Not one robotics club member expected anything to go wrong.

As the day of the competition arrived, emotions were high. The team felt a mix of both fear and excitement. At VEX competitions, robots are always checked for illegal parts. There are strict rules in their game manuals disallowing materials not produced by VEX, unless they’re comparable to the official parts.

The robotics team made it through inspections with no issues, going on to win several rounds. Only after the third match did problems start to appear. As they were waiting to be queued after the third match, opposing teams began to call them out for the 3D part.

So, the team had their robot inspected. This time, things were different. Because the part wasn’t produced by VEX, it was illegal for use in the competition. Traditionally, VEX bans 3D-printed parts that aren’t used for decoration. As more teams compiled issues against the ELHS robot, judges gave the team two options. They could either stop using the part, rendering a big part of the robot almost unusable or be disqualified from the competition.

“We were desperate,” Bowles said. “Even if you suck, it’s better to be in the competition and learn, to get experience from it. Because watching videos on YouTube- it’s a completely different thing than being there.”

They chose to stay. For the rest of the competition, the team had to keep their motors unplugged, which set them back immensely. It was clear that removing the insert had set rival teams forward. There was an entire segment the robot couldn’t compete in, just because the motors were removed. As the competition went on, the team started losing more matches.

After returning back from the competition, the team has since been working tirelessly to avoid any drawbacks during their next competition, which takes place in January. Because the robot they built wouldn’t work without the 3D printed part, they had to redesign the robot from scratch.

In order to make their new robot work, the team has created comparable parts by combining smaller Vex pieces, or drilling into fragments like gears.

Still, Michael Barger (11), president of the robotics club, is hopeful that this new robot will be the key to taking them all the way through the state competition.

“We can manage that,” Barger said. “Our robot so far is coming along very nicely. And I think it’ll be a winner.”

Ky Bey is a member of the class of 2024 and the Social Media Editor for Portrait. This is her second year on Portrait as a senior. Ky's favorite thing...

Quinn Martin is a member of the Class of 2024 and is the Photo Editor of Portrait. He has been on staff since his sophomore year during the 2021-22 school...